Ms.Rosita Chen

Supplier

2022-09-26

China

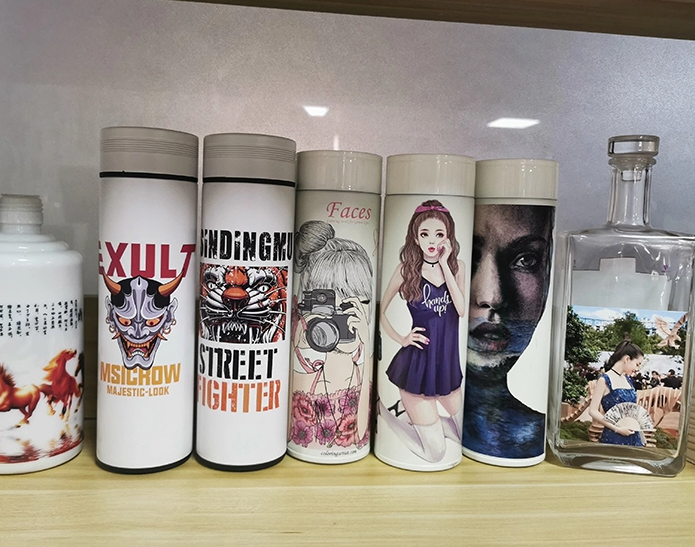

Since the late 19th century, pad printing has been a popular method of marking and decorating products. However, the progress of UV digital technology, more specifically, UV printers, and the demand for customized products in short-term production have attracted many people from pad printing to digital printing. Although pad printing is still the preferred solution for irregular parts and some substrates, ink-jet printing has achieved success with its ability to print full-color graphics, generate one-time graphics and generate high-quality imaging.

What is pad printing?

Pad printing is a traditional method of transferring 2D graphics to 3D objects. It is required to use laser plate making machine or exposure unit to etch the image into the printing plate or platitude. For each new work of art, a new plate or platitude must be etched. Before printing, mix solvent based ink with appropriate proportion of ink, solvent and hardener, and fill each ink cup. Once the machine is started, the ink cup will move over the etching cliche and fill the etching with ink. The ceramic ring (attached to the ink cup) will scrape or remove excess ink from the etching, so only a small amount of ink can be picked up. Then, the silicone pad will be pressed on the ink, picked up, and transferred to the substrate. When using multiple colors, make sure that all colors are correctly registered before printing.

What do you want to buy or inquire, please search directly

Scan uses

small programs

© 1999-2022 宁波搜点网络科技有限公司 All rights reserved. 浙ICP备19009040号

Intellectual Property Protection - Privacy Policy - Terms of Use

法律声明免责声明:本站系所有用户均可免费发布信息,本站所有信息由各公司自行发布,请在交易前确认真实合法性,本站不承担任何法律责任,如有侵权请联系我们客服电话:0574-87020551