| Min. Order: | |

| Price: | 1000.0~100000.0 |

| Port: | China |

| Place of Origin: | Ma'anshan,China |

| Settlement Method: | L/C,D/P,D/A,T/T |

| Transportation Method: | Shipping,Air freight |

| Company: | Haco CNC Machine(Anhui)Manufactory Co.,Ltd |

| Contacts: | Cameron Lee |

| Mail: | Info@Accurl.com |

| Phone: | 18855551088 |

| Website: | http://www.accurlcnc.com/add/contact/ |

| PV: | 244 |

Supplier

Haco CNC Machine(Anhui)Manufactory Co.,Ltd

Model No.:HSP-5000T

Production Capacity:75 sets/25day

Delivery Date:25day

Raw Material:Sheet / Plate Rolling

Extra Services:Plating / Coating

Certification:CE

Brand Name:HACO

Ram Stroke Length:500mm

Max.Opening Height:1100mm

Hydraulic system:Bosch rexroth from Germany ...

Main motor:Siemens

Means of Transport:Ocean,Land

Packing:Wrapped in plastic to prote...

Power:300HP

Machine Type:Press Brake

Automation:Automatic

Material / Metal Processed:Stainless Steel

Hydraulic Press Model Number:HSP-5000T

Press Capacity:5000tons

Work Table size:1650*1350mm

Electrical system:Schneider from France

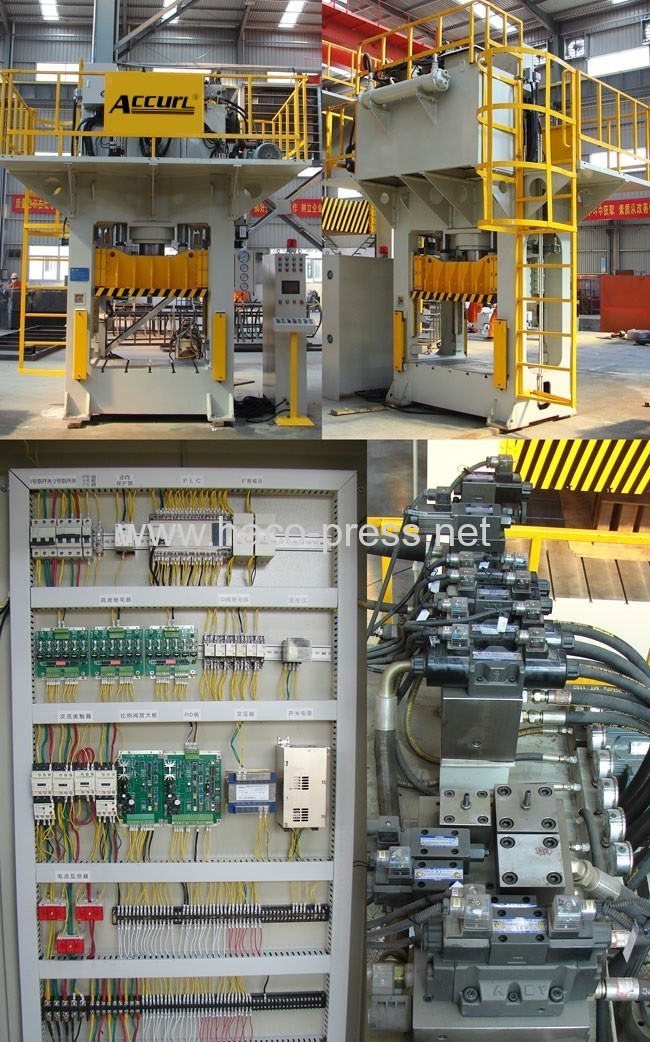

1.Hydraulic Press 5000T for CE & SGS

2.Bosch hydraulic system

3.Low noise & high speed

4.High Quality

5.High Safety Protection

H Frame Serie Hydraulic Press 5000 ton Hot Forming Press 5000t For Carbon Fiber

Characteristics:

1) The press is available up to 1~6000 Tons capacity as per customers' requirements. Each press is subjected to rigorous simulation through FEA (Finite Element Analysis) design testing before manufacturing. Stress testing software for structural rigidity is utilized to ensure each press to meet demanding standards. High capacity press is preferred in H Frame structure.

2) Advanced and systemized Taiwan hydraulic system, Taiwan TWOWAY integrated cartridge valve oil circuit allow little fault, low noise level, minor reversing impact but high reliability.

3) Eight sides of brass guide rails of full stroke length not only ensure high accuracy but also allow easy adjustment of slide leveling.

4) The press is well equipped with safety devices as per CE standards, like two sides locking device and CE Mark light curtain protection sensors. Mitsubishi PLC and 7 / 10 inch Taiwan Weinview touch screen make the machine easy for operation and specification adjustable.

5) Compression molding press is equipped with advanced technique of adjustable air breathing system. The slow opening after the curing point helps in avoiding jerk movement.

6) The press is featured by slow decompression to eliminate hydraulic shock, RAM pre-fill system with side cylinders for fast closing speed and proportional valving for controlling closing speed and compression rate.

7) Each press is manufactured under strict quality control management with good quality components from France, Japan, Germany, USA and Taiwan to assure the best performance and accuracy.

8) Each press is equipped with a Die Change Trolley for easy die change with lower cost than moving bolster.

Optional:

1) Touch Screen Display (HMI)

2) Heating available by Electric Heaters / Heat Transfer Oil / Steam

3) Trolley / Moving Bolster for easy die change

4) Cushion Device for anti-shock while stamping

5) Water Cooler / Oil Chiller

6) Mould Stripping Device

7) Air breathing design as per request

8) Accumulators for fast speed and low energy consumption

Applications:

Compression moulding press is specially designed for composite production industry, like moulding of SMC/BMC/DMC/FRP.

Different applications of the press include the following: SMC sanitary wares, SMC electric box, satellite dish, biogas digester, SMC auto parts and more.

| MAKE of Major Accessories | |||

| No. | Item | Standard MAKE | High Standard MAKE |

| 1 | PLC | Mitsubishi | Siemens |

| 2 | Motor | WanNan/China top brand | Siemens / Rexroth |

| 3 | Pump | Anson/Taiwan, Yuken/Japan | Siemens / Rexroth |

| 4 | Servo Pump | DAIKIN/Japan | DAIKIN/Japan |

| 5 | Solenoid Valve | Yuken/Japan | Atos/Italy, Rexroth |

| 6 | Directional Valve | Yuken/Japan | Atos/Italy, Rexroth |

| 7 | Proportional Valve | Yuken/Japan | Atos/Italy, Rexroth |

| 8 | Cartridge Valve | Jeou Gang/Taiwan,SUN/USA | SUN, Atos, Rexroth |

| 9 | Prefill Valve | TAI COLN/Taiwan | Atos/Italy, Rexroth |

| 10 | Electric Units | Schneider/France | Schneider/France |

| 11 | Light Curtain | LNTECH with CE Mark | LNTECH with CE Mark |

| 12 | Touch Screen | Weinview/Taiwan | Siemens |

| 13 | Pressure Gauge | SKON/Taiwan | SKON/Taiwan |

| 14 | Hydraulic Manifold | MADE IN TAIWAN | MADE IN TAIWAN |

| No worse quality components are adopted in Accurl presses. | |||

What do you want to buy or inquire, please search directly

Scan uses

small programs

© 1999-2022 宁波搜点网络科技有限公司 All rights reserved. 浙ICP备19009040号

Intellectual Property Protection - Privacy Policy - Terms of Use

法律声明免责声明:本站系所有用户均可免费发布信息,本站所有信息由各公司自行发布,请在交易前确认真实合法性,本站不承担任何法律责任,如有侵权请联系我们客服电话:0574-87020551